- 10 gigabit (10Gb) home network – Part I

- 10 gigabit (10Gb) home network – Part II

- Again, Amazon?

- 10 gigabit (10Gb) home network – Zone 1 switch

- 10 gigabit (10Gb) home network – Zone 2 switch – Part 1

- 10 gigabit (10Gb) home network – Zone 2 switch – Part 2

- 10Gb home network – Retrospective

- Quanta LB6M

- 10 gigabit home network – Summary

- Revisiting the Quanta LB6M

- MikroTik CRS317 10GbE switch

- MikroTik CSS610

- Quieting the MikroTik CRS317

- Goodbye, MikroTik

- Troubleshooting 2.5Gb power over Ethernet

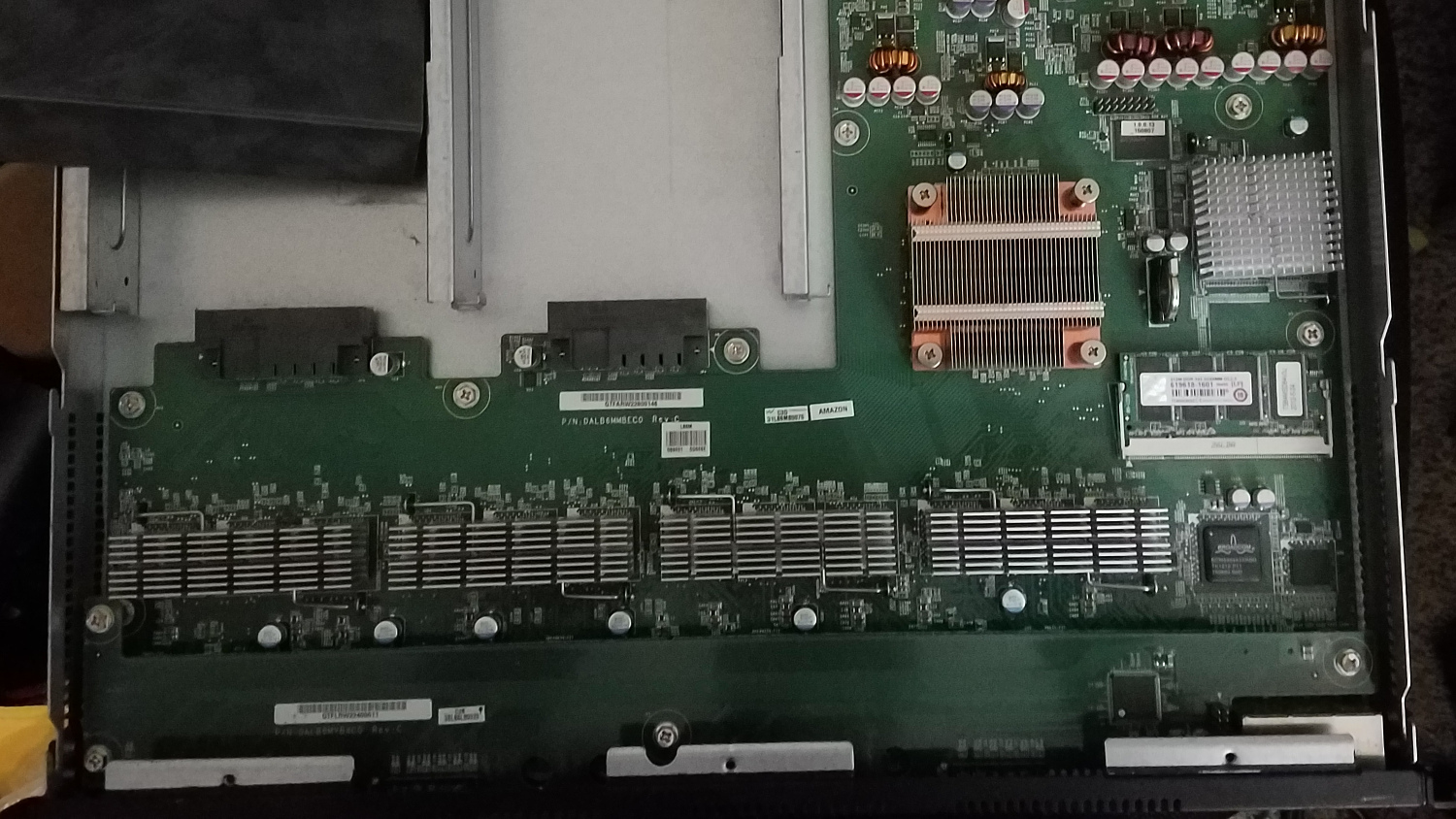

Back in January of this year, I acquired a Quanta LB6M to upgrade my home network to 10GbE, at least for the primary machines in the group. In recently also acquiring a better rack for mounting that switch plus a few other things, I noticed the switch becoming painfully hot to the touch on the underside.

Now immediately after receiving the switch, I swapped out the 40mm fans on the switch’s sled to alleviate a very noticeable, high-pitched whine. The fans I replaced them with I knew weren’t going to draw air nearly as well, but all indications online were the switch shouldn’t overheat.

Yet the switch was obviously overheating. Thankfully it didn’t appear the switch was malfunctioning, but just getting so hot that I couldn’t touch the switch without feeling like I was going to burn myself.

I moved a fan to blow air on it to alleviate that as much as possible as a temporary measure, knowing I’d eventually have to pull it out and open it up. Let’s just say I should’ve done this before initially deploying the switch.

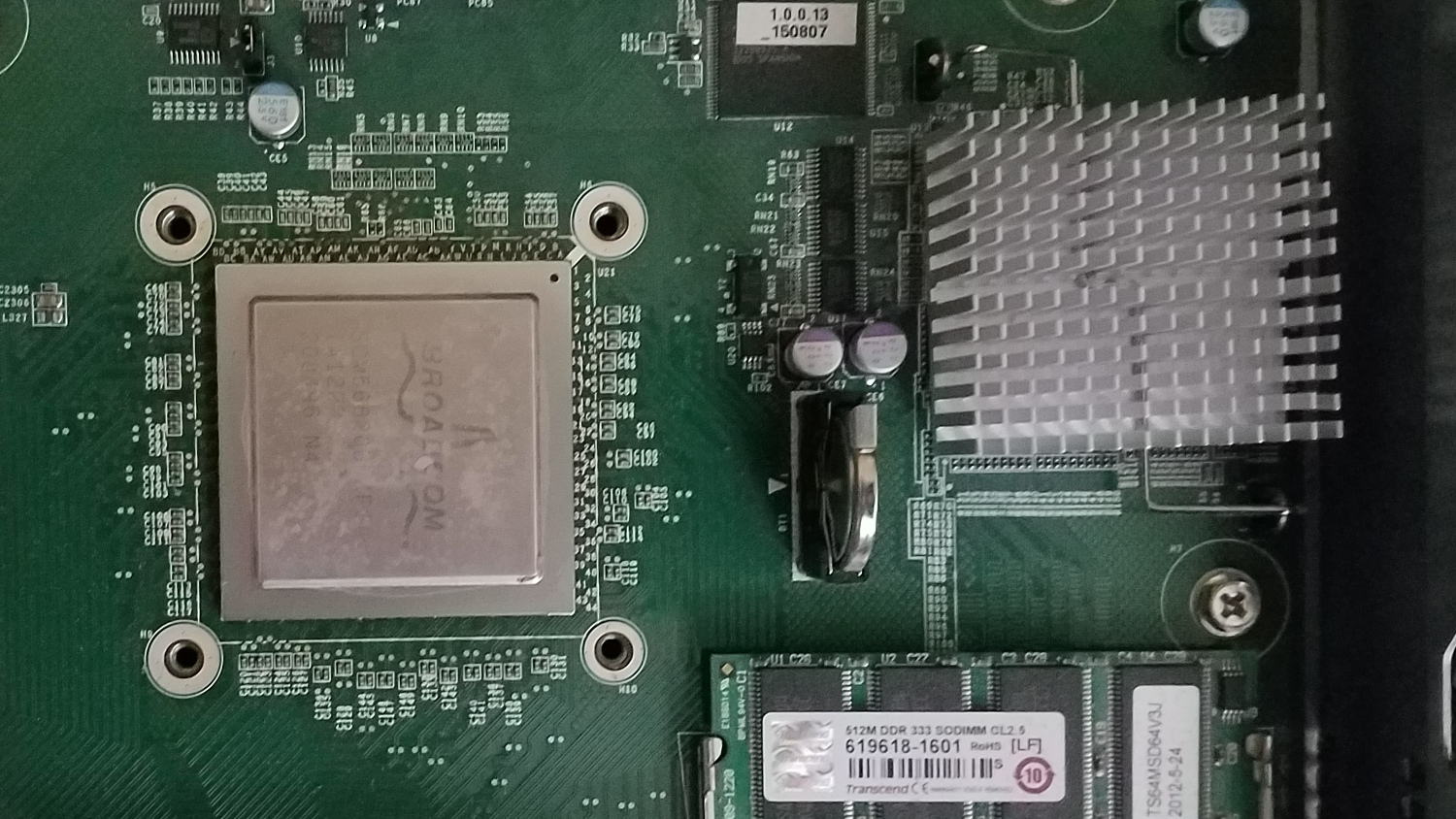

In removing the copper heatsink from the primary processor, it was obvious my switch was not refurbished in any fashion. Normally when you remove a heatsink from a processor, thermal compound stays behind and you end up with some on the processor and the heatsink.

Almost none stayed on the processor. And what attached to the heatsink had hardened and needed to be scraped off. In hindsight I should’ve followed up with a metal polish, but ArctiClean took care of it well enough.

So did this help? Not really. Still don’t regret doing it, though, as it very obviously needed to be done. But there was something else I failed to notice while I had the switch off the rack: the fan sled.

Anymore today, ventilation around fans tends to be honeycomb to maximize airflow. The type of grill you see above, however, is obviously not the right kind for airflow. Perhaps that’s why Quanta felt the need to put 40mm fans (AVC DB04028B12U) on this thing that rival 80mm fans on airflow. And no I’m not joking on that. They move A LOT of air at a pretty good static pressure, but are LOUD!

And the 40mm fans I have in there currently don’t come anywhere close to what the stock fans allowed. So cut the fan grills and everything’s good, right?

For the most part. The switch is still getting noticeably warm to the touch, but not the scald-your-hand hot it was previously. And an increased airflow was the first thing I noticed after powering on the switch after opening up the sled.

So both definitely needed to be done. If I’d opened the fan sled without changing the thermal compound, it wouldn’t have made nearly the difference. And no I’m not posting a picture of the metalwork I did to do this. I’ll just say that I wish I had a better setup to get a cleaner result. But it works, at least.

You must be logged in to post a comment.